In the past year of 2023, electric vehicle sales have achieved a rapidly rising market revolution and demonstrated greater acceleration ambitions for the future. For many countries, 2025 will be a time point for a certain goal. Practice in recent years has proven that transportation electrification is a sustainable energy revolution that is committed to tackling the climate crisis and serving the green ecosystem. Consumer surveys show that EV charging is a key barrier to EV adoption. In other words, if consumers believe that EV charging is reliable, convenient, easy, and affordable, then their willingness to buy EVs will be stronger.

As a key part of the electric vehicle charging system, the charging connector’s adaptability, reliability, and performance directly affect the charging efficiency of EVs and the charging experience of car owners. Although the standards for charging connectors worldwide are not unified, even some are retreating from this game. However, understanding the types of charging connectors is still meaningful for the long-term development of EVs and the reuse of some old electric models.

According to the charging type, EV charging can be divided into direct current(DC)and alternating current(AC). Power from the grid is always alternating current, while batteries need to store power in the form of direct current. DC charging requires a converter built into the charger to convert alternating current into direct current so that a large amount of energy can be quickly obtained and transferred to the EV’s battery. AC charging requires the onboard charger in the car to convert AC power into DC power and store it in the battery. So, the fundamental difference between the two methods is whether the converter is in the charger or the car.

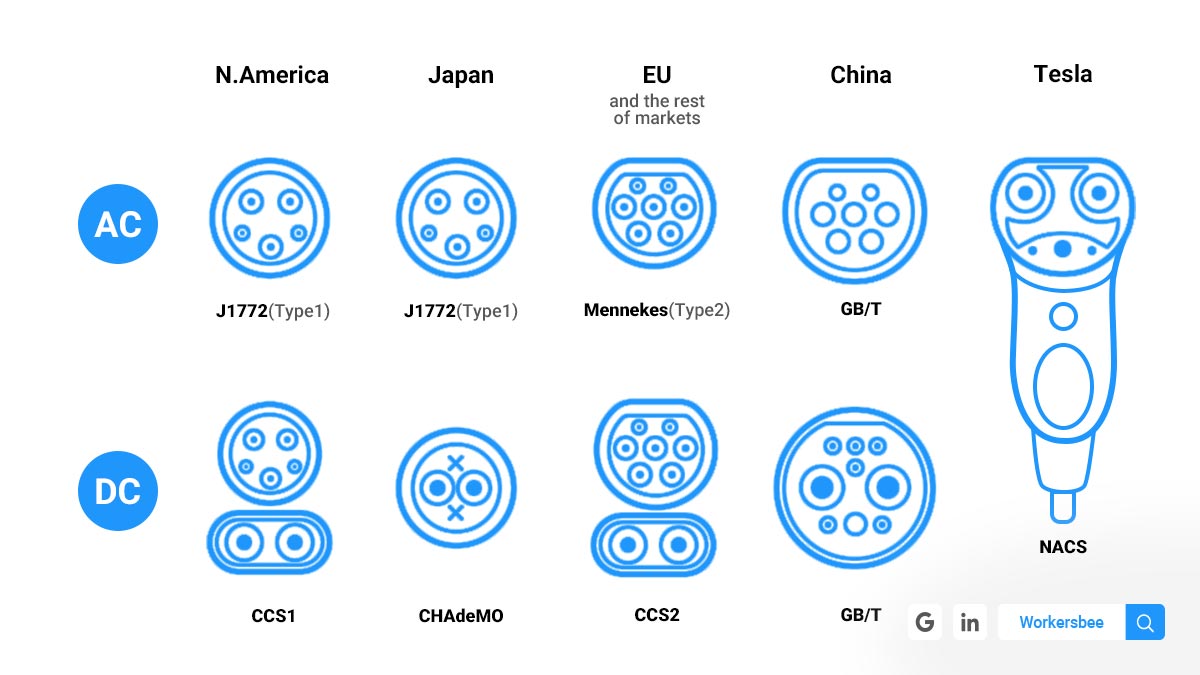

As shown in the figure above, with the development of the electric vehicle industry so far, automakers have formed several mainstream charging connector standards based on different sales regions. AC Type 1 and DC CCS1 in North America, and AC Type 2 and DC CCS2 in Europe. Japan’s DC uses the CHAdeMO, and some also use CCS1. The Chinese market uses the GB/T standard as the national electric vehicle charging standard. In addition, EV giant Tesla has its unique charging connector.

AC Charging Connector

Home chargers and chargers in public places such as workplaces, shopping malls, hotels, and theaters are currently mainly AC Chargers. Some will have a charging cable attached, some will not.

J1772-Type 1 Connector

Based on the SAE J1772 standard and designed for use with 120 V or 240 V single-phase AC systems. This AC charging standard is used in North America and Asia, such as Japan and Korea, and supports only single-phase AC charging rates.

The standard also defines charging levels: AC Level 1 up to 1.92kW and AC Level 2 up to 19.2kW. Current public AC charging stations are almost exclusively Level 2 chargers to meet people’s parking charging needs, and Level 2 home chargers are also very popular.

Mennekes-Type 2 Connector

Designed by Mennekes, it has been defined by the European Union as the AC charging standard for the European market and has been adopted by many other countries. It can be used to charge EVs by 230V single-phase or 480V three-phase AC power. The maximum power of three-phase electricity can reach 43kW, which greatly meets the charging requirements of EV owners.

In many public AC charging stations in Europe, to be compatible with the diversified EV market, charging cables are usually not attached to the chargers. EV drivers usually need to carry their charging cables (also called BYO cables) to connect the charger to their vehicles.

Workersbee recently launched EV charging cable 2.3, which not only maintains its consistent high quality and high compatibility but also uses terminal rubber-covered technology to achieve a perfect protection experience. At the same time, cable management is optimized taking into account consumer usage scenarios. The design of the cable clip and Velcro makes it easy and enjoyable for consumers to use every time.

China’s national standard connector for EV charging is very similar to Type 2 in outline. However, the direction of its internal cables and signal protocols are completely different. Single-phase AC 250V, current up to 32A. Three-phase AC 440V, current up to 63A.

In recent years, with the explosive growth of China’s EV exports, GB/T connectors have quickly become popular in the international market. In addition to China, there is also a large demand for GB/T connector charging in the Middle East and CIS countries.

Although the debate about the pros and cons of AC and DC is very hot, with the large-scale popularization of EVs, it is urgent to increase the number and proportion of fast DC charging.

Combined Charging System: CCS1 Connector

Based on the Type 1 AC charging connector, DC terminals (Combo 1) are added for high-power DC fast charging up to 350kw.

Although the Tesla charging connector mentioned below is crazily eating up the market share of CCS1, CCS1 will still have a place in the market due to the protection of the previously announced subsidy policy in the US.

Workersbee, a long-established charging connector supplier, still has not given up its market in CCS1, keeping up with policy trends and actively optimizing its products. The product has passed UL certification, and its reliability and safety have been unanimously praised by customers.

Besides the Americas, Japan and South Korea will also adopt this DC charging standard (of course, Japan also has its own CHAdeMO DC connector).

Combined Charging System: CCS2 Connector

Similar to CCS1, CCS2 adds DC terminals (Combo 2) based on the Type 2 AC charging connector and is the main connector for DC charging in Europe. Unlike CCS1, the AC contacts (L1, L2, L3, and N) of Type 2 on the CCS2 connector have been completely removed, leaving only three contacts for communication and protective grounding.

Workersbee has developed natural cooling connectors with cost-effective advantages and liquid cooling ones with efficiency advantages for CCS2′s high-power DC fast charging connectors.

It is worth mentioning that the CCS2 natural cooling charging connector 1.1 can already achieve a stable continuous output of up to 375A high current. The amazing method of controlling temperature rise has attracted great attention from automakers and charging equipment manufacturers.

The liquid cooling CCS2 connector facing future needs can currently achieve a stable current output of 600A. The medium is available in oil cooling and water cooling, and the cooling efficiency is higher than natural cooling.

CHAdeMO Connector

DC charging connectors in Japan, and some charging stations in the US and Europe also provide CHAdeMO socket outlets, but they are not mandatory policy requirements. Under the market squeeze of CCS and Tesla connectors, CHAdeMO has gradually shown weakness and has even been included in the list of “not considered” by many charging equipment manufacturers and operators.

GB/T DC Connector

China’s latest revised DC charging standard increases the maximum current to 800A. It is a great benefit to the emergence of new electric models with large capacity and long range on the market, accelerating the popularity and development of fast charging and supercharging.

In response to market feedback about the poor performance of the DC connector lock retention system, such as the connector being prone to falling or unlocking failure, Workersbee has upgraded the GB/T DC connector.

The locking strength of the hook is increased to avoid failure of connection with the vehicle, improving reliability and user experience. In addition, it not only improves the stability of the electronic lock but also adopts a quick-replacement design, which reduces maintenance costs for high-frequency use.

Tesla Connector: NACS Connector

The integrated design for both AC and DC is half the size of the CCS connector, elegant and light. As a maverick automaker, Tesla named its charging connector standard the North American Charging Standard.

This ambition also became a reality not long ago.

Tesla has opened up its charging connector standard and invited other car companies and charging networks to use it, which has a huge impact on the charging market.

Giant automakers including General Motors, Ford, and Mercedes-Benz have successively joined. Recently, SAE has also standardized it and defined it as J3400.

ChaoJi Connector

Led by China and jointly developed by many countries, the ChaoJi connector combines the advantages of the current mainstream DC charging connectors, improves defects, and optimizes various regional compatibility, aiming to globally achieve higher currents and future-proof expansion requirements. The technical solution has been unanimously approved by the IEC and has become an international standard.

However, under the fierce competition from NACS, the future of development is still unclear.

The unification of charging connectors can improve the interoperability of charging equipment, which will undoubtedly benefit the widespread adoption of EVs. It will also reduce the input costs of automakers and charging equipment manufacturers and operators, and promote the accelerated development of transportation electrification.

However, due to the restrictions of government policies and standards, there are also barriers to interests and technologies between various automakers and charging equipment suppliers, making it extremely difficult to unify global charging connector standards. The direction of charging connector standards will follow market choices. The share of the consumer market determines which parties will have the last laugh, and the rest may merge or disappear.

As a pioneer in charging solutions, Workersbee is committed to promoting the development and standardization of connectors. Both our AC and DC products have won a good reputation in the market and have made positive contributions to the development of the charging industry. We always look forward to working with outstanding leaders in the industry to build a green transportation future.

Workersbee provides our partners with better electric vehicle charging solutions with high-quality products, cutting-edge technology, and strong production strength.

Post time: Jan-12-2024