In the post-fuel-vehicle era, climate issues are intensifying, and solutions to climate problems have been high-level items on the to-do lists of governments. It is a global consensus that the adoption of electric vehicles is an effective means to improve the climate. To increase the adoption of EVs, there is one topic that can never be avoided – electric vehicle charging. According to many consumer market surveys, car consumers rank the unreliability of charging as the third major obstacle to purchasing EVs. The entire process of EV charging involves the grid resiliency provided by the power infrastructure and the construction of charging stations that meet market demand. What connects them to these exciting electric vehicles are EV charging cables. To activate a larger electric vehicle sales market, EV charging cables, as a key part, may be facing or will face the following challenges.

1.Reasonably Increase the Charging Speed

The ICE vehicles we have become accustomed to usually only take a few minutes to fill up, and there is usually no need to queue. So in public perception, refueling is a quick thing. As a new star, EVs generally need to be charged for several hours or even overnight. Although there are many fast chargers now, it takes at least half an hour. This strong contrast in “refueling time” makes charging speed a key factor hindering the popularity of EVs.

In addition to the power provided by the charger, the factors that affect the EV charging speed also need to consider the battery capacity and reception capabilities of the car itself, and very importantly – the transmission capacity of the charging cable.

Due to space planning limitations of charging stations, to ensure that the charging ports of electric vehicles in different positions can be easily connected to the charging ports of the chargers, the charging cables will have an appropriate length, so that car owners can operate them effortlessly. The reason why we say “appropriate length” is because while ensuring the accessibility of the charging connector, it may also mean an increase in cable resistance and current transmission loss. So a reasonable balance must be struck between these two interests.

The resistance during charging comes from the conductor resistance and the contact resistance of the cable and pins. Current cable and pins connection technology usually adopts the crimping method, but this method will lead to higher resistance and higher power loss. Given the high demand for high current output in DC charging, Workersbee’s new generation DC charging cable uses ultrasonic welding technology to bring the contact resistance close to zero and allow greater current to pass. Its excellent electrification performance has attracted the attention and consultation of many well-known charging equipment manufacturers around the world.

2.Effectively Solve Temperature Rise Problems

During the charging process, there is a strong connection between the temperature of the charging cable and the charging speed. On the one hand, the transfer of current generates heat. As the current increases, the heat increases, causing the resistance to increase. On the other hand, as the temperature of the conductor increases, the resistance increases, which also causes the current to decrease.

The rising temperature of cables and connectors also poses certain safety risks, as high temperatures may lead to malfunction or even failure of components, or may cause a fire. Therefore, chargers usually have safety settings for over-temperature protection and over-current protection. The temperature signal is mainly transmitted to the charger control center through the temperature monitoring points of the equipment, such as some thermistors, to make the response about reducing the current or protective power off.

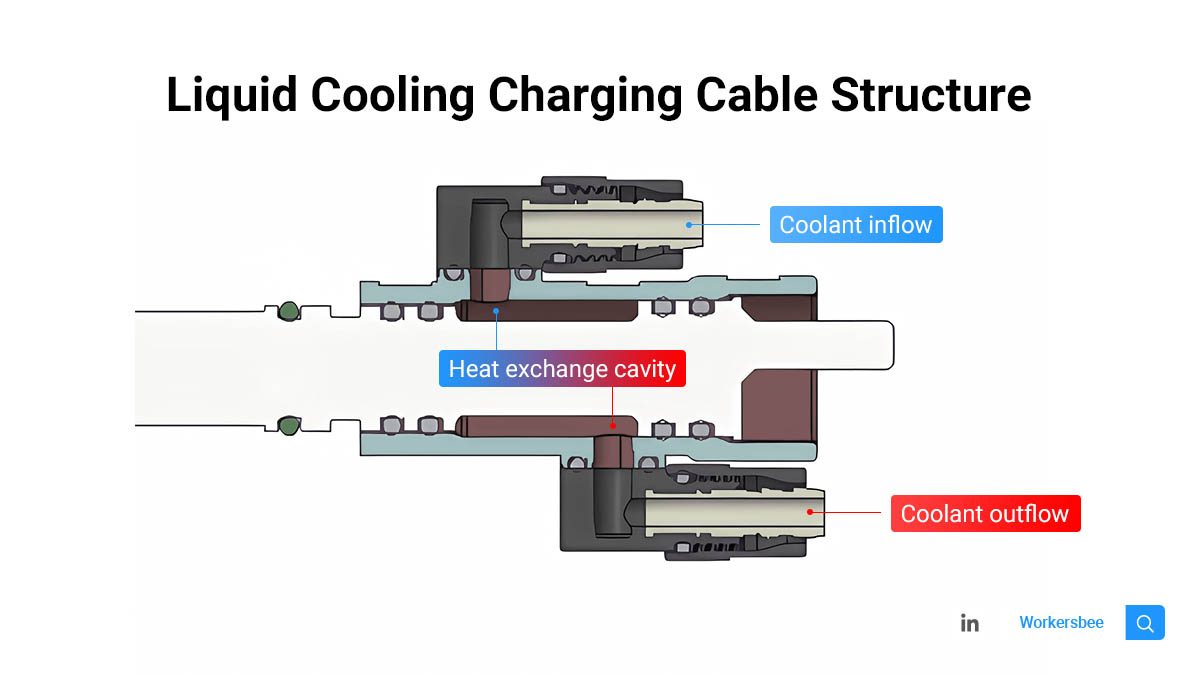

Beyond real-time monitoring to control device temperature, timely heat dissipation of charging cables is the main solution to solve temperature rise. Usually divided into two solutions: natural cooling and liquid cooling. The former relies more on the air duct design of the equipment to increase the cross-sectional area of the cables and form strong air convection to achieve natural heat dissipation. The latter mainly relies on the cooling medium to conduct and exchange heat to achieve heat dissipation, and the heat exchange efficiency is much greater than natural cooling. At the same time, liquid cooling technology requires less cross-sectional area of cables, allowing the design of charging cables to be thinner and lighter.

3.Improve User Experience

The final say in rating charging cables should be left to users, including EV owners and charging network operators. It is effortless to use and worry-free to maintain. If such high praise is achieved, I believe it will make us more confident in the future of electric vehicles.

More lightweight: Especially for high-power DC charging piles, the outer diameter of the cable can be smaller while ensuring heat dissipation. Make the cable more lightweight, even for people with weak strength are also easy to operate.

More comfortable flexibility: The soft cable is easier to bend and feels more comfortable to hold. It also makes the cabling performance more outstanding and the installation easier. Workersbee charging cables are made of high-quality TPE and TPU with good flex but creep resistance, excellent elasticity and strength, not easy to deform, and more hassle-free maintenance.

Stronger durability and weather resistance: Consider the raw materials and structural design to avoid sheath cracking due to UV and heat fatigue during hot seasons. Also, it will not harden or lose flexibility in the cold winter, and there is no need to worry about weathering damaging the cable.

Provide an anti-theft lock: Prevent the car from suddenly unplugging the charging cable by someone during the charging process, disrupting charging.

4.Meet Strict Certification Standards

For the electric vehicle charging industry, which is still in development, certification standards are a hard threshold for products to enter the market. Certified charging cables are monitored to ensure that each batch meets the standards, so they are more reliable, safe, and trustworthy. Charging cables are used not only to supply power to EVs but also for communication, so their safety is crucial.

In the European and American markets, mainstream certifications mainly include UKCA, CE, UL, and TUV. Regulations and safety requirements need to be applied to the local market, and some are mandatory requirements for obtaining subsidies. To pass these certifications, it usually has to go through several rigorous tests, such as pressure tests, electrification tests, submersion tests, etc.

5.Future Trend: High-power Fast Charging

As the battery capacity of EVs increases, the charging speed that requires overnight charging is not enough for most people. How to achieve safer and more convenient fast charging is an issue that the entire transportation electrification industry needs to consider. Thanks to the rapid heat exchange of liquid cooling technology, the current high power can reach 350~500kw. However, we know that this is not the end,and we hope that charging an EV can be as fast as refueling an ICE vehicle. When a higher charging current is used, liquid cooling charging may also reach a bottleneck. At that time, we may need to try more breakthrough solutions. Some studies have proposed that phase change material technology may become a new solution, but it may take a long time before it enters the market.

6.Future Trend: V2X

V2X means the Internet of Vehicles, which refers to the communication links and impacts established by cars and other facilities. The application of V2X can help us better manage energy and transportation safety. It mainly includes V2G (grid), V2H (home)/B (building), V2M (microgrid), and V2L (load).

To realize V2X, two-way charging cables need to be applied to achieve efficient energy transmission. This will change our understanding of electric vehicles, enable flexible loads, access to more flexible energy, and expand energy storage in the grid. Transmission of power and data from or to the vehicle in an interconnected or energized manner.

7.Future Trend: Wireless Charging

Like today’s mobile phone charging, large-scale wireless charging may also be implemented for electric vehicle charging in the future. This is a revolutionary technology and a big challenge for charging cables.

Power is transmitted through the air gap, and magnetic coils inside the charger and those inside the car charge inductively. There will be no more mileage anxiety, and charging will be possible at any time when the electric car is driving on the road. By then, we will probably say goodbye to charging cables. However, this technology requires very high infrastructure construction, and it should take a long time for it to be widely popularized.

Charging cables need to effectively transmit data so that EVs and the charging network can establish a reliable connection, while also being able to provide fast charging current and be able to withstand external environmental factors such as temperature that may affect charging performance. Workersbee’s years of research and development in the field of charging cables have given us advanced insights and diverse solutions. If you would like to know more, please let us know.

Post time: Nov-28-2023