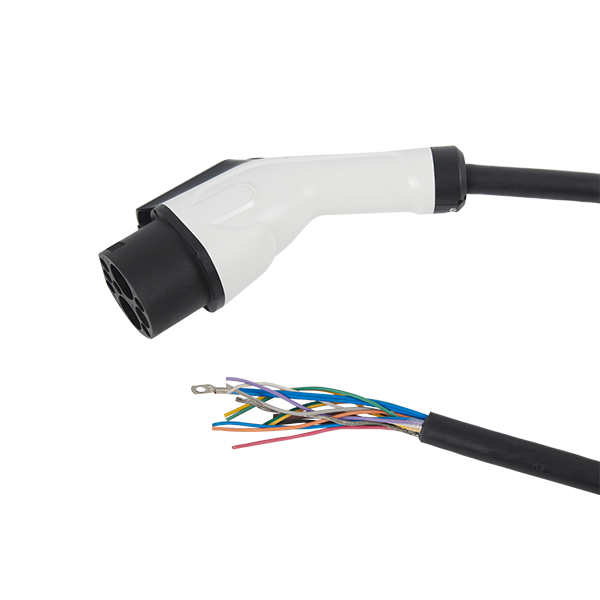

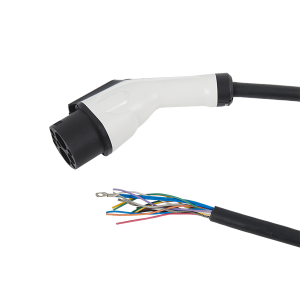

Top Manufacturer Open End EV Charging Cable With GBT EV Plug

Features

Safe Charging

This GB T EV charging plug is designed to be a component with the crimp terminal with an integrated coating process. Its waterproof level can reach IP67, even if the electric vehicle owner uses it in a very humid coastal area, it is very safe.

Cost Efficient

The product’s modular design is integrated seamlessly with automated batch manufacturing technology. Automated production improves production capacity and efficiency, and makes the production process of products more standardized. At the same time, the production cost is also reduced, so that customers can better benefit from it.

OEM/ODM

This end-free GB/T EV plug highly supports customization. Not only the appearance of the EV plug, but also the length and color of the EV cable, and even the terminal at the other end can also be customized. Our conventional terminals include round insulated terminals and tubular insulated terminals. If customers have special requirements, please contact us.

Universal Compatibility

This EV Cable can be adapted to different models, and the end can be selected with an insulation segment, bare end terminal, etc. Support customization, Almost all charging piles on the market can customize the corresponding end-free EV cable for customers.

| Rated Current | 16A-32A Single Phase |

| Rated Voltage | 250V AC |

| Operating Environment Temperature | -40℃- +60℃ |

| Insulation Resistance | 500MΩ |

| Withstand Voltage | 2500V&2mA Max |

| Flammability Rating | UL94V-0 |

| Mechanical Lifespan | >10000 Mating Cycles |

| Protection Rating | IP67 |

| Certification | Compulsory testing/CQC Temperature Rise |

| Temperature Rise | 16A<30K 32A<40K |

| Operating Temperature | 5%–95% |

| Insertion & Withdrawal Force | <100N |

| Base Structure Material | PC |

| Plug Material | PA66+25%GF |

| Terminal Material | Copper alloy, electroplated silver |

| Wiring range | 2.5 – 6 m² |

| Warranty | 24 months/10000 Mating Cycles |

Workersbee Group is one of the leading companies in the EV plug industry. One out of every two GB T EV plugs is produced by Workersbee Group. The quality of the Workersbee Group EV plug has been verified by the market and has been recognized by these authoritative partners.

One of the key factors instilling confidence in collaboration with esteemed enterprises is Workersbee’s state-of-the-art fully automated production line. This cutting-edge facility not only ensures a robust production capacity but also guarantees adherence to meticulous product production specifications, further cementing Workersbee’s credibility in the industry.

At Workersbee, prioritizing product safety holds paramount importance. Through steadfast research and development efforts, they continuously strive to enhance the safety features of their EV plugs. By seamlessly integrating and standardizing the processes of research and development, production, sales, and service, Workersbee ensures a holistic approach to delivering exceptional products to their customers. This comprehensive and streamlined approach underscores Workersbee’s commitment to providing a reliable and well-rounded experience for their clientele.